TM66

TM66 Assured

The TM66 Assured Product Verification Scheme launched Created by the Lighting Industry Association and endorsed by CIBSE, we are proud to have participated in its development.

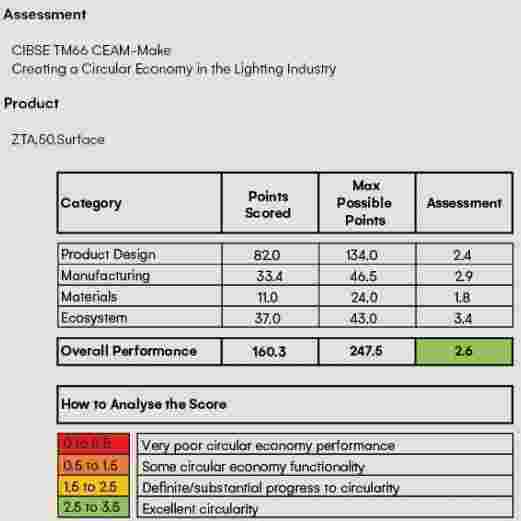

ZTA.50.Surface has been put through its paces as our first product to receive this official external verification. We’re delighted that this exists; especially as it supports our view that circularity claims should be quantified. With The LIA’s independent verification, ZTA.50.Surface remains at the top level, achieving a score in the Excellent Circularity category. The LIA external assessment reviewed our product and agreed with our self-assessed score of 2.6.

This programme advances our industry’s circular economy practices and promotes transparency and credibility; something we are thrilled to see, as strong advocates of durability, repairability and circularity in product design.

Stoane Lighting have become a trusted source to unpick environmental jargon and make sense of the industry’s changing sustainability landscape; this result gives us confidence that we’re on the right track.

Introduction

Friday 29th October 2021 saw the launch of CIBSE SLL's new Technical Memorandum TM66.

Entitled: ‘Creating a Circular Economy in the Lighting Industry’, TM66 describes a Circular Economy’s main aims, how it can be achieved and what it’s practice will mean to the different branches of our industry like specifiers, manufacturers, contractors and Facilities Managers.

We have discussed the latest EcoDesign regulations. This has clauses concerning the Circular Economy, such as its requirement that lamps and control gear should be replaceable within a luminaire so their lives can be extended via easy maintenance and repair. This is a good example of a design practice towards a Circular Economy. Circular Economies are about keeping products in use to minimise material extracted from the earth’s crust, waste generated and emissions during all the stages involved.

Making lamps and gear replaceable is only a starting point toward a Circular Economy luminaire design. A comprehensive list of principles is detailed in CIBSE’s TM66.

CEAM-Make

Written by CIBSE's lighting division, the Society of Light and Lighting, TM66 includes a Circular Economy Assessment Method for Manufacturing (CEAM-Make). CEAM-Make's list of 72 searching questions, the majority of which ask for back-up evidence, is split into four sections.

- Product Design: covering topics such as design for long life and repair.

- Materials: covering topics like usage of recyclable materials rather than virgin.

- Manufacturing: covering topics like additive and subtractive techniques and localisation.

- Ecosystem: covering topics like repair or upgrade services to complement circular economy design and manufacturing.

The outcome of the assessment is a single figure rating by which product comparisons can be made.

What does it mean for our products?

As with the EcoDesign regulations, Stoane Lighting welcome TM66 and its contribution to a more sustainable lighting industry. Of course we have always tried to practice Circular Economy principles but to have an industry checklist from such a renowned organisation as CIBSE to interrogate our designs and service we consider a major step forwards.

We were honoured to critique early versions and comment on iterations to the now published version 1.0. We say 1.0 being quite sure it will evolve in line with practice and legislation in this fast-moving territory.

What does it mean for your spec?

A TM66 score demonstrates a product's performance in the context of a Circular Economy. Achieving a score that is excellent or substantial progress to circularity is no mean feat, and we believe it will become an important support tool for specification.

Note that a second CEAM tool has been published alongside CEAM-Make: it's called CEAM-Specify. This contains a subset of the most important questions from CEAM-Make, resulting in a first pass at a luminaire Circular Economy assessment. We feel this will speed adoption of TM66 in the industry as manufacturers work on full CEAM-Make assessments. We expect that specifications will ask for a CEAM-Make assessment, with minimum scores for the four headings and perhaps also pulling out specific individual questions pertinent for the project in hand.

We have made some changes to our website to include a new tab where you can download assessments for a number of our standard products. Check out ZTA.50.Surface here.

Jargon Buster

- Circular Economy - A circular economy is based on the principles of designing out waste and pollution, keeping products and materials in use, and regenerating natural systems.

- Design for Disassembly - Design principle that calls for the end-of-life options of how the product, components and materials can be deconstructed.

- Design for Repairability - Design principle that calls for products to be manufactured using fasteners, materials and processes that allow them to be easily be fixed.

- Eco Design - Design principle that calls for the minimization of negative environmental and health impacts across a product or service's life cycle.

- Embodied Carbon - The amount of carbon emitted during the making of a product.

- End of Life - The life cycle stage during which a product no longer has value to its original owner and is then disposed of.

- Environmental Product Declaration (EPD) - An EPD is a document that communicates the environmental performance or impact of any product or material over its lifetime. It can be used to compare different products or materials in order to select the most sustainable option.

- Footprint - The impact of a product or service across its life cycle. For example, a product's carbon, water, energy and material footprints.

- Operational Carbon - The amount of carbon emitted during the operational or in-use phase of a building.

- Life Cycle - All of the stages that a product goes through in its lifetime: raw material extraction, processing, manufacturing, use, end-of-life and transportation

- Life Cycle Analysis (LCA) - A method to evaluate the environmental impacts of a product or system over its life cycle.

- Linear Economy - A linear economy traditionally follows the “take-make-dispose” step-by-step plan. This means that raw materials are collected, then transformed into products that are used until they are finally discarded as waste.

- Product Environmental Footprint (PEF) - A multi-criteria measure of the environmental performance of a good or service throughout its life cycle.

- Recycling - The collection, sorting and processing of disposed materials for use in another manufacturing process.

- Remanufacturing - Process of recovery, disassembly, repair and sanitizing components or parts for resale and reuse.

- Sustainability - Balance of Social, Environmental and Economic Performance

- Upcycling - Use of secondary products, components or materials that results a higher economic value of that material.

- Waste Electrical and Electronic Equipment (WEEE) - Disposed electronic and electrical products. These products typically contain hazardous materials and require certified handling and recycling.

- Zero Waste - Program to divert all (at least 95%) waste from landfill. The scope of zero waste may or may not include incineration depending on reference.

For a more complete glossary, please see Lighting Industry Association Technical Statement 41.