Sustainability

The aim of this item is to discuss our ZTA range proliferation and the foundation sustainability considerations that have gone into its design. We go through this in some depth under two headings, each of which we underpin with dedicated white papers and CPDs.

ZTA

Our ZTA family is growing. Along with all Stoane Lighting products, ZTA has been designed to ensure as low a through-life environmental impact as possible.

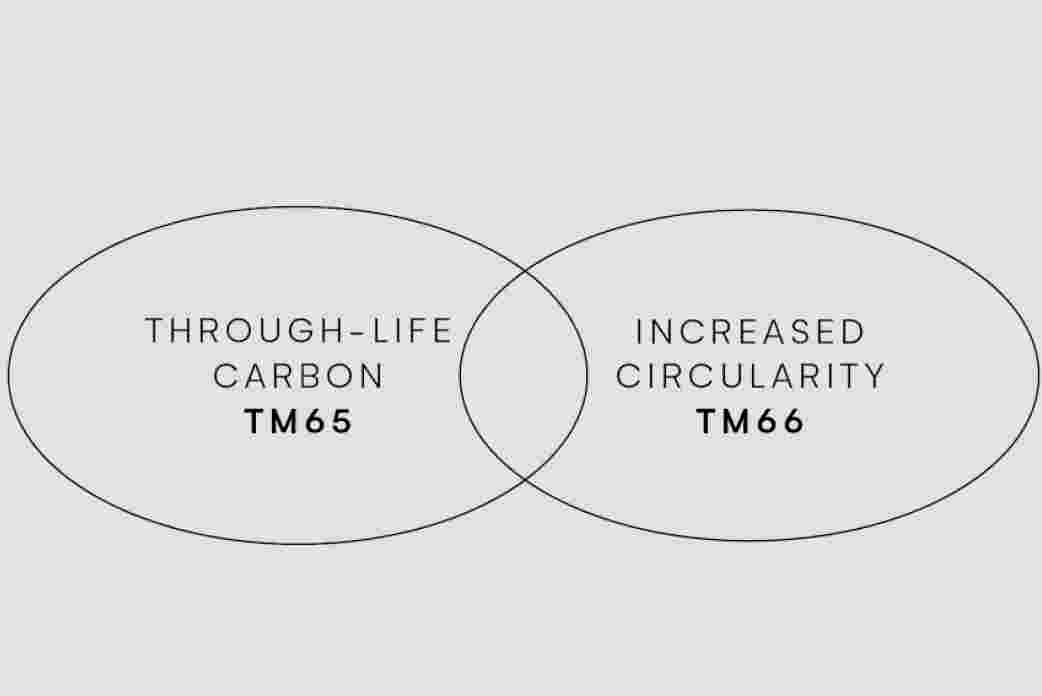

There are two main aspects to a luminaire's environmental impact: through-life carbon and circularity.

Through-life Carbon

Lowering initial embodied carbon in a product is essential to reach net zero carbon emissions by 2050 and lower the risks of irreversible climate change. The metric we use is CIBSE's TM65 Embodied Carbon in Building Services: A Calculation Methodology. Reports for our ZTA range can be found in the Environmental tab of their product page.

This is the topic of a complementary white paper and CPD entitled: Luminaire Design for Low Environmental Impact: Through-life Carbon Analysis.

Circularity

Having made our luminaire the next point is preserving the embodied energy in it by retaining its utility, i.e. keeping the initial embodied carbon ‘working’. This involves Circular Design principles like long life and repairability. By keeping products in use, the greenhouse gas emissions associated with new production and end of life treatment are reduced while providing the same benefit.

The metric we use to measure this is CIBSE | SLL’s TM66: Creating a Circular Economy in the Lighting Industry. Reports for our ZTA range can be found in the Environmental tab of their product page.

This is the topic of a complementary white paper and CPD entitled: Luminaire Design for the Circular Economy.

Sweet Spot

A lowering of through-life carbon and an increasing of circularity results in lowest possible environmental impact.

A real-life product example is the pendant addition to our ZTA range: ZTA.50.PLP. Plastic Light Pendant uses unavoidable waste material from the previous production of other ZTA luminaires, demonstrating the lowering of its initial embodied carbon and perfect circularity.

What's next?

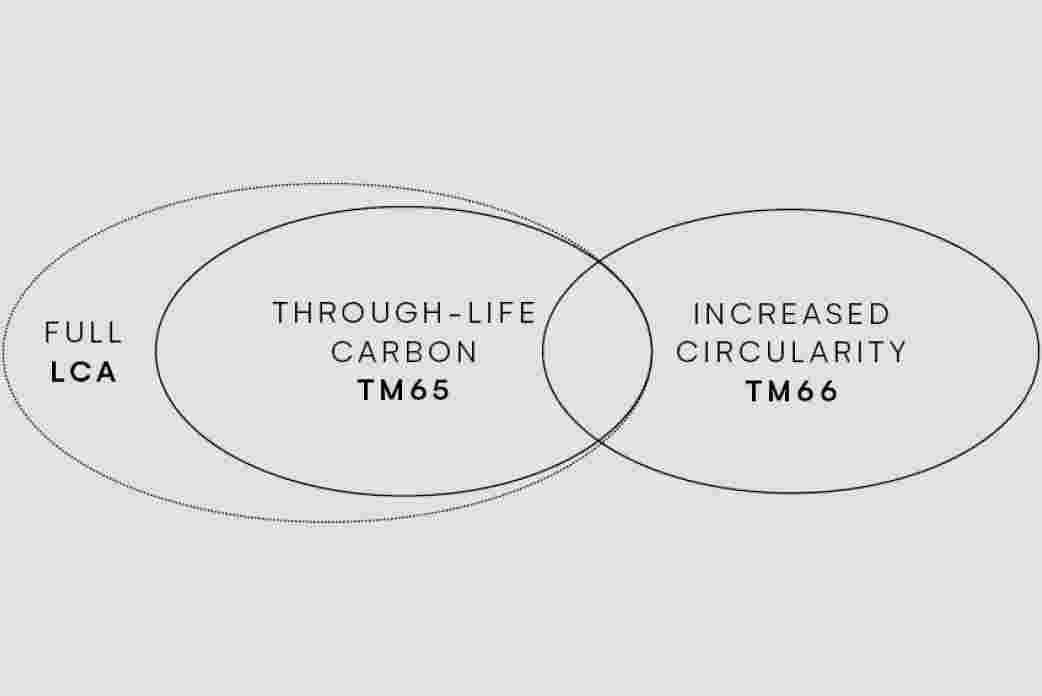

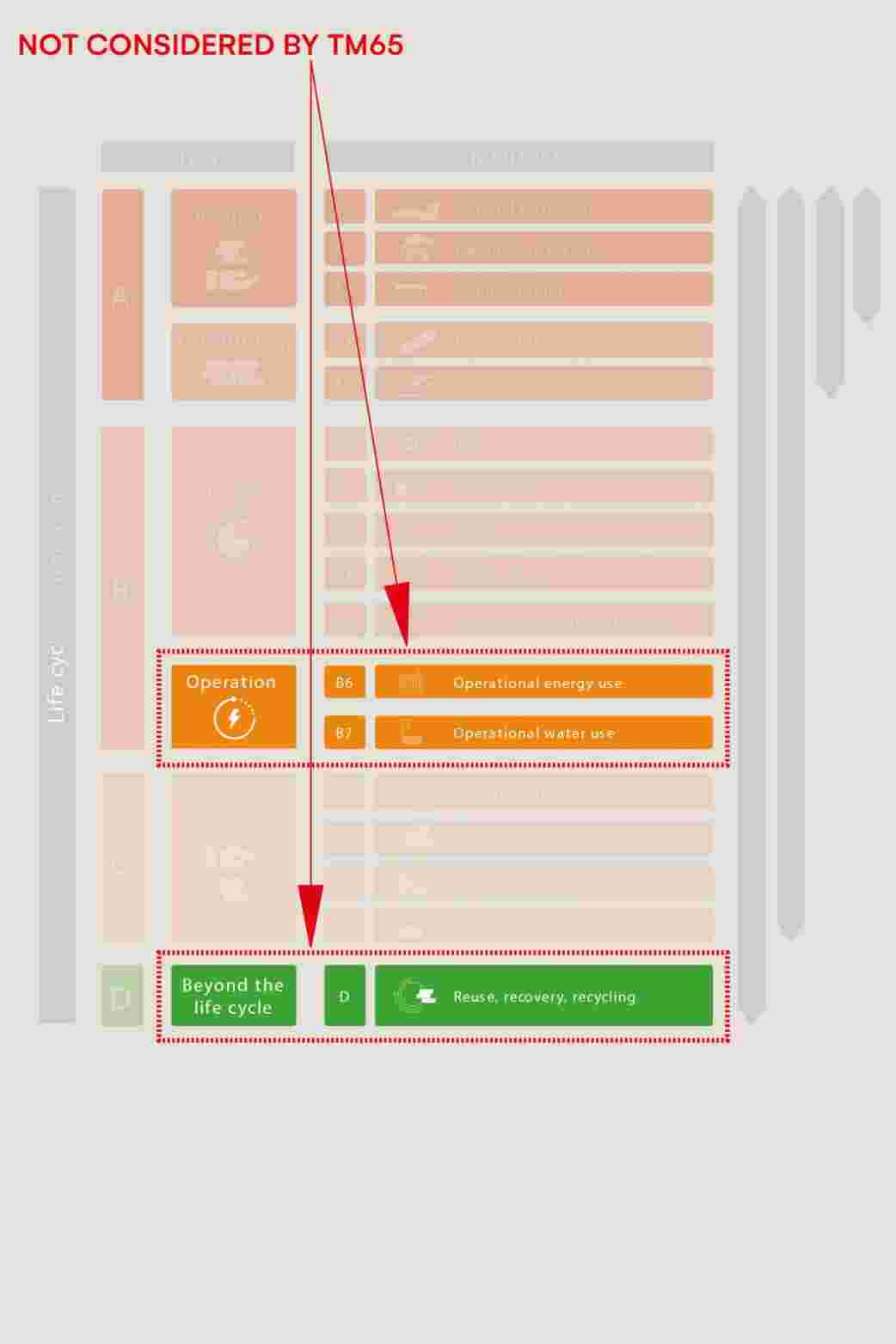

You may ask why another ellipse on our Venn diagram covering Life Cycle Analyses (LCAs). It’s true that this has been covered by TM65 above under the heading ‘through-life carbon’. TM65 is a fast-to-execute LCA that gives a good answer to a product’s Global Warming Potential (GWP). It does not cover all inputs though and two gaps are the ‘Operational energy use’ phase (B6) and the ‘Beyond the life cycle phase (D). It also does not cover other environmental input indicators besides GWP.

So for a full ‘through-life carbon’ study a full LCA must be undertaken. This we have carried out at Stoane Lighting on one of our products in the ZTA range (ZTA.50.LV Stucchi). The outcomes are discussed in detail in the CPD and ‘white paper’ entitled: ‘Luminaire Design for Low Environmental Impact: Through-life Carbon Analysis’ mentioned above.

- Regarding phase B6 we found that a 95CRI light source increases the Global Warming Potential of the in-use stage by approximately 10% compared to a 90CRI source (comparing otherwise identical modules from the same supplier). B6 influences heavily a product’s total environmental impact. This raises fundamental issues in terms of our light source, driver and optical system specifications because B6 related impact is tied to luminaire system efficiency, lm/circuit W, CRI choice is just one influence on this. To take the example given of using a CRI 95 source compared with a CRI 90 source, knowing there is an efficacy trade-off, which should be specified? This of course will be application specific and it’s the expertise of the lighting designer that comes into play, looking at the benefits and burdens project by project. Alerted by the outcome of the LCA analysis however, generally at Stoane Lighting we are reviewing all light sources and drivers that we use looking at the integral balance of light quality benefits (think CRI, flicker, etc.) alongside burdens (energy consumption) with lifetime being the third axis.

- Regarding phase D, re-using some of the product components not only reduces the impact of the End-of-Life waste treatment of that product, but it also reduces the environmental impact of the new product, by avoiding the burdens of extracting and manufacturing a portion of materials. An example of this is the complete housing, including active components, of the ZTA Zoom being re-used with a recycled acrylic acrylic powder coat shade to make our ZTA.50.PLP (Plastic Light Pendant).

- Regarding other environmental impact categories, the full LCA study carried out in the CPD and white paper mentioned above showed the impacts of producing ZTAs from an aluminium extrusion compared with extraction from a solid bar. In fact the difference for the impact category GWP was negligible. This is due to the fact that the manufacturing operations to produce both versions of the fitting are the same, with a small difference in the mass of the component. But for the other categories clearer increases in the impact of using a solid bar were observed. The abiotic depletion of fossil fuels and the ozone layer depletion are affected by the use and transport of natural gas, coal and oil. Terrestrial and aquatic ecotoxicity, photochemical oxidation and acidification categories are mainly associated to the extraction of aluminium and other metals and to heat and electricity production, whilst the eutrophication category is mostly affected by the treatment of landfill.

We hope this brief discussion on full LCA studies gives you a flavour of the wealth of information they unearth and how avenues for improvement to a manufacturers’ designs and processes can be quantified.

What LCA?

The next question is of course "what LCA?". We used the LCA software SimaPro developed by Pre’ Sustainability and equipped with the Ecoinvent 3 database. This was provided by Napier University in the framework of our KTP project. The data was modelled using the calculation methodology CML baseline, developed at the University of Leiden.

There is no universal LCA methodology though, and this is a huge issue. Different manufacturers’ products cannot necessarily be compared even though each is able to justify their claims. The EU Commission is promoting the use of Product Environmental Footprint methods in its relevant policies and the PEP Association wrote in 2018 some Product Specific Rules for luminaires, PSR 14. This is being updated now with LE joining at the drafting table. Expect more news on this breakthrough in 2023.