TM65 and TM65.2

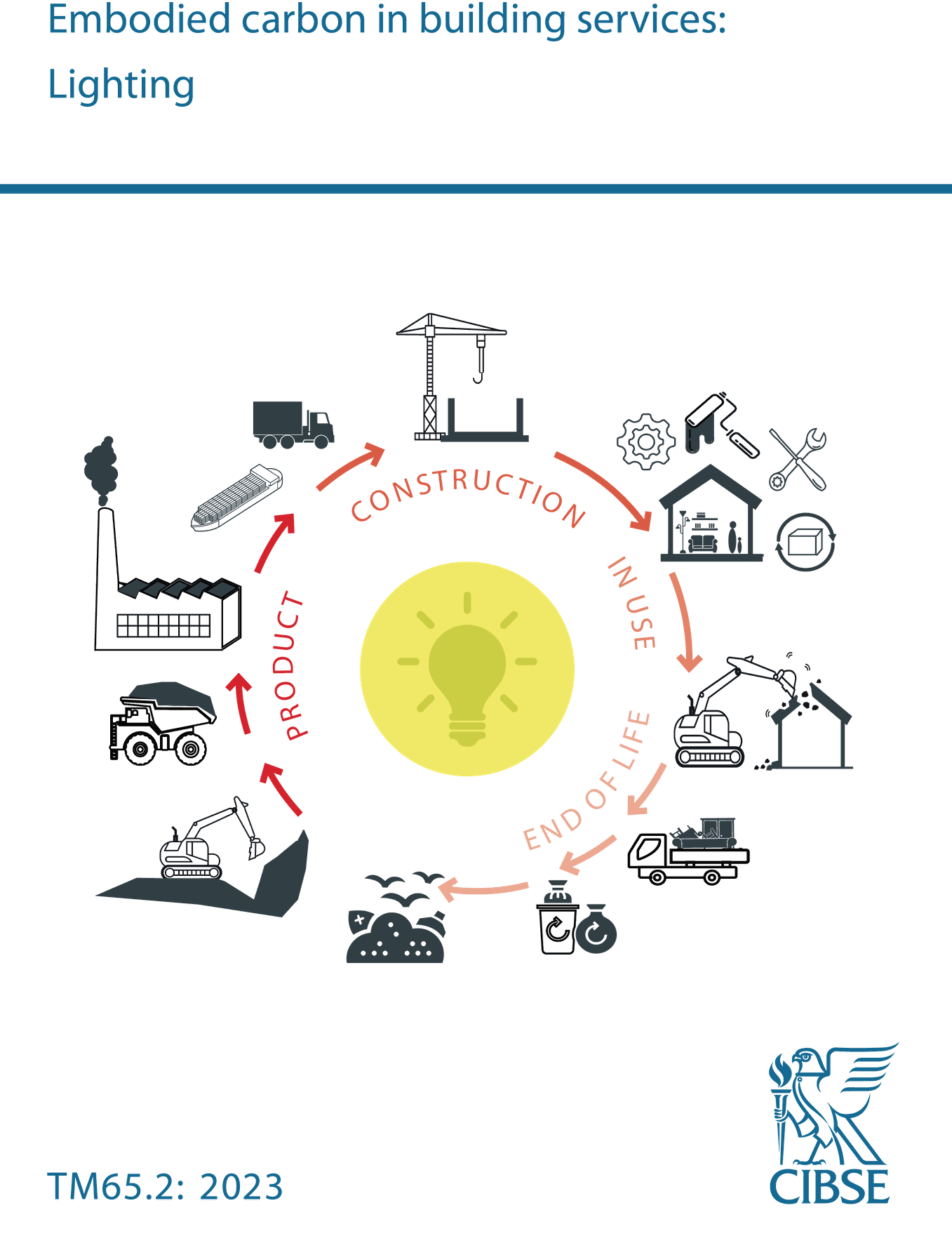

CIBSE TM65 Embodied carbon in building services was launched in 2021 as a gap-bridging embodied carbon quantification methodology aimed at manufacturers in the MEP sector.

TM65 was introduced to give manufacturers the possibility to move the first steps in the sustainability assessment field. However, to be able to keep the methodology simple, TM65 had to rely on some assumptions and approximations, often leading to results that were overestimating the embodied carbon impacts, compared to the results of a Life Cycle Assessment.

To refine the accuracy of the embodied carbon results for lighting products, in 2023, TM65.2 Embodied carbon in building services: Lighting was published, which produces results more in line with LCA values. The update saw our Sustainability Lead coordinating the technical aspects of the work.

In summary

Thanks to our in-house knowledge on TM65, we are also able to use it to evaluate the benefits of remanufacturing approaches in projects; you can find some more information looking at The Holburne Museum, showing that remanufacturing can potentially help avoid over 70% of an installation’s embodied carbon.

We also acknowledge that embodied carbon should also be considered from a product lifetime perspective: being able to offer low embodied carbon luminaires that only last for 5 years before needing to be replaced potentially produces more environmental burdens than having a slightly higher embodied carbon luminaire that will last for 25 years with only minimal maintenance.

We think it’s important to apply this perspective when looking at TM65 results, this is why we report the lifetime timeline on our TM65 reports, showing the product being first built at the start and repaired once halfway-through its life to fulfil the 25 year-lifetime we commit to ensure.

It is also important to remember that the environmental burdens of products do not just stop at their embodied carbon. We make sure that we evaluate different aspects of the sustainability of our products, including their circularity and burdens in other environmental impact categories which can be calculated through Life Cycle Assessment.