Captured Waste

"Waste isn't waste until you waste it"

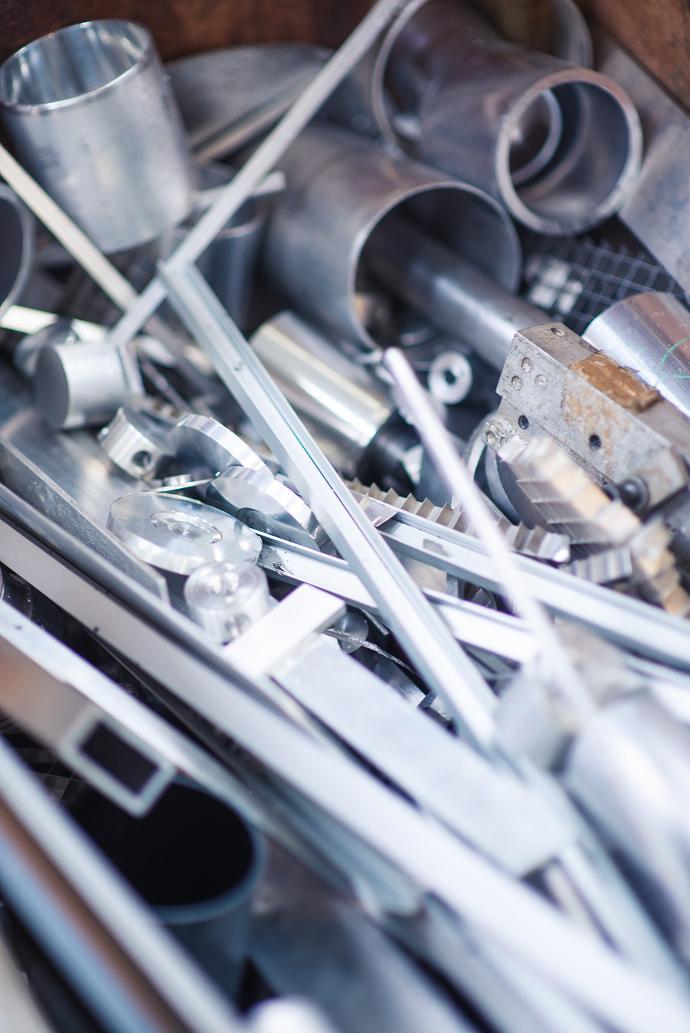

Producing waste is often inevitable during manufacturing processes, however at Stoane Lighting, we can demonstrate using waste as a resource. We believe that if the best light for the planet is the one that is never made, then certainly the next best light for the planet is one that is made from captured waste.

For this reason we have pursued innovative ideas to make a better use of our manufacturing waste, rather than just recycling it, aligning with the principles of the circular economy.

In this section you will find information, including our

efforts to produce decorative pendants made from 100% manufacturing offcuts or from captured powder overspray and acrylic waste.

Casting Light Pendant

Plastic Light Pendant

Similarly to CLP, PLP was born from an opportunity to put our waste to use. Our dry powder-coating paint, whilst VOC free, does generate a small amount of overspray waste. Over time this accumulates into relevant amounts to warrant investigation.

After numerous failed approaches, by working with Midton on the west coast of Scotland, we perfected a technique of capturing the powder waste, and if desired granulated acrylic waste too, in a PMMA monomer binder. We have yielded a novel material and a new, decorative product to join our circular ZTA range: ZTA.50.PLP.

We also believe that innovation is blended inextricably with sustainability. Traditionally our aluminium waste would be collected by a local subcontractor and taken to be recycled, however when considering the cost and energy that this process requires, we decided to explore ways in which we could use a low value by-product and with minimal energy investment, convert it to a high value item.

Using an all-electric forge, the molten aluminium is poured into a homemade steel mould.

The whole process takes place in-house: the manufacturing, the

production of aluminium offcuts and the forging of the pendants.

According to Life Cycle

Assessment, waste materials used as raw materials in a product

system bear no environmental burdens; however, some burdens are still

associated with the energy and additional resources necessary to produce the

new product. 100% of the aluminium used to fabricate the Casting Light Pendant shade comes from manufacturing offcuts. The energy involved in the smelting and casting process is electricity

generated by 100% renewable sources.

PLP can be generated from waste in different ways, based on the powder waste and acrylic content:

- 12% captured fine powder waste, 88% clear acrylic

- 40% granulated clear acrylic waste, 60% clear acrylic

- 12% captured fine powder waste, 45% granulated clear acrylic waste, 43% clear acrylic

Additionally, CLP has been designed as a circular product as a part of our ZTA range: mounting a ZTA.50 core, its central components are interchangeable with those of a ZTA.50 spotlight, opening up the opportunity for simple reconfiguration or upgrade.

In order to advance this otherwise discarded by-product, we were determined not just to use waste for its own sake but to add value. We have created something beautiful and viable. It satisfies a genuine requirement and does so without requiring virgin resources.

This pendant blends excellent light quality, circularity and flexibility, whilst repurposing waste acrylic and avoiding the dispersion of fine powder waste into the environment. Having perfected the process on the PLP shade, it is now a technique that is gradually infiltrating the rest of our range where virgin PMMA was previously used.

Not only is the solution cost neutral for the customer, it provides effects than many prefer.